The Process

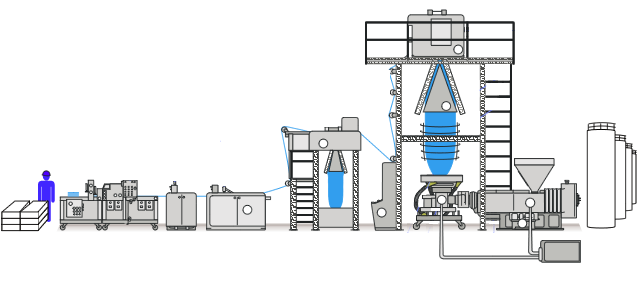

The process of creating plastic begins with small beads, known in the industry as resin. Additives are mixed with the resin to customize the plastic with different properties (color, anti-static, UVI, etc.), and the raw compound travels through the extruder, melting as it undergoes intense heat. Next, the molten plastic enters the die, forming the polymer into a ring, which is blown upward three stories into a bubble.

A chiller cools both the material and the machine. The plastic is then flattened as it comes down and cooled a final time.